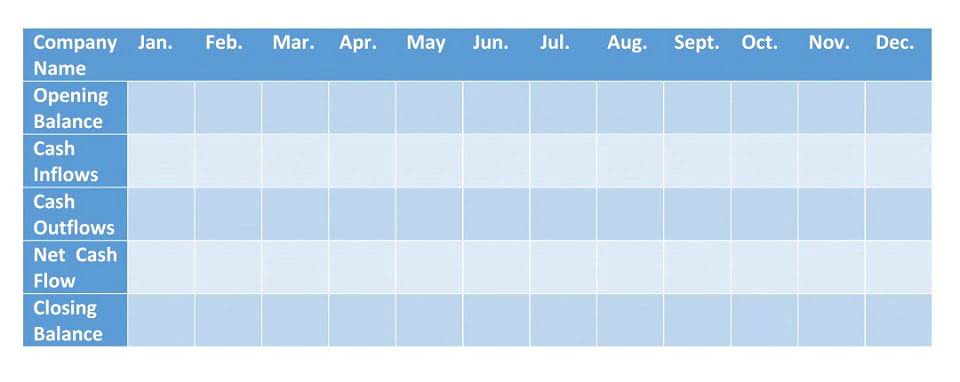

It is important to include indirect costs that are based on this overhead rate in order to price a product or service appropriately. If a company prices its products so low that revenues do not cover its overhead costs, the business will be unprofitable. For example, the total direct labor hours estimated for the solo product is retained earnings 350,000 direct labor hours. With $2.00 of overhead per direct hour, the Solo product is estimated to have $700,000 of overhead applied. When the $700,000 of overhead applied is divided by the estimated production of 140,000 units of the Solo product, the estimated overhead per product for the Solo product is $5.00 per unit. The computation of the overhead cost per unit for all of the products is shown in Figure 6.4.

Formula for Predetermined Overhead Rate

The most prominent concern of this rate is that it is not realistic being that it is based on estimates. Since the numerator and denominator of the POHR formula are comprised of estimates, there is a possibility that the result will not be close to the actual overhead rate. The fact is production has not taken place and is completely based on previous accounting records or forecasts. For example, the recipe for shea butter has easily identifiable quantities of shea nuts and other ingredients.

Predetermined Overhead Rate (POR) Formula

The application rate that will be used in a coming period, such as the next year, is often estimated months before the actual overhead costs are experienced. Often, the actual overhead costs experienced in the coming period are higher or lower than those budgeted when the estimated overhead rate or rates were determined. At this point, do not be concerned about a predetermined overhead rate includes the accuracy of the future financial statements that will be created using these estimated overhead allocation rates. You will learn in Determine and Disposed of Underapplied or Overapplied Overhead how to adjust for the difference between the allocated amount and the actual amount.

What is your current financial priority?

This involves categorizing all overhead costs and regularly analyzing them to identify potential savings. The key is choosing an appropriate cost driver – like machine hours in manufacturing or headcount in sales – to distribute overhead expenses. Therefore, this predetermined overhead rate of 250 is used in the pricing of the new product. Companies need to make certain the sales price is higher than the prime costs and the overhead costs.

- It’s also important to note that budgeted figures in calculating overhead rates are used due to seasonal fluctuation/expected changes in the external environment.

- This rate is then used to apply overhead costs to products during the period.

- This record maintenance and cost monitoring is expected to increase the administrative cost.

- It would involve calculating a known cost (like Labor cost) and then applying an overhead rate (which was predetermined) to this to project an unknown cost (which is the overhead amount).

- However, the difference between the actual and estimated amounts of overhead must be reconciled at least at the end of each fiscal year.

Practical Application of Overhead Rates in Business

Let’s assume a company has overhead expenses that total $20 million for the period. The company has direct labor expenses totaling $5 million for the same period. In these situations, a direct cost (labor) has been replaced by an overhead cost (e.g., depreciation on equipment). To account for these changes in technology and production, many organizations today have adopted an overhead allocation method known as activity-based costing (ABC).

Operating Expenses Vs Overhead Expenses

One of the advantages of predetermined overhead rate is that it can help businesses monitor overhead rate. This comparison can be used to monitor or predict expenses for the next project (or fiscal year). During the year, if XYZ produces a table that requires 4 direct labor hours, $40 ($10 per hour x 4 hours) of overhead costs would be allocated to that table. In order to find the overhead rate we will use the same basis that we have chosen by multiplying this basis by the calculated rate.

Also, profits will be affected when sales and production decisions are based on an inaccurate overhead rate. Hence, it is essential to use rates that determine how much of the overhead costs are applied to each unit of production output. This is why a predetermined overhead rate is computed to allocate the overhead costs to the production output in order to determine a cost for a product. The predetermined overhead rate is, therefore, usually used for contract bidding, product pricing, and allocation of resources within a company, based on each department’s utilization of resources. Suppose that X limited produces a product X and uses labor hours to assign the manufacturing overhead cost. The estimated manufacturing overhead was $155,000, and the estimated labor hours involved were 1,200 hours.

Accounting Jobs of the Future: How Staffing Agencies Can Help Land Them

- With $2.00 of overhead per direct hour, the Solo product is estimated to have $700,000 of overhead applied.

- Both figures are estimated and need to be estimated at the start of the project/period.

- The estimated or budgeted overhead is the amount of overhead determined during the budgeting process and consists of manufacturing costs but, as you have learned, excludes direct materials and direct labor.

- However, the problem with absorption/traditional costing is that we have to ignore individual absorption bases and absorb all overheads using a single level of activity.

- If you’d like to learn more about calculating rates, check out our in-depth interview with Madison Boehm.

So, if you wanted to determine the indirect costs for a week, you would total up your weekly indirect or overhead costs. You would then take the measurement of what goes into production for the same period. So, if you were to measure the total direct labor cost for the week, the denominator would be the total weekly cost of direct labor for production that week. Finally, you would divide the indirect costs by the allocation measure to achieve how much in overhead costs for every dollar spent on direct labor for the week. Since overhead costs cannot be easily traced to individual products like direct material or labor costs, overhead rates help to allocate a fair share of these costs based on the activity of making the product. This allows businesses to capture the full cost of production in their accounting.